Breather Valve / Vent Valve / Flame Arrestor / Pig Launching

Since 1983, ERGIL, through its ERGIL StorageTech™ brand, has supplied the oil, petrochemical and chemical industries with high quality tank storage equipment.

From a modern manufacturing plant in Mersin, Turkey, ERGIL StorageTech™ produces a range of storage tank internal equipment, such as floating suction system, oil skimmers, and external floating roof drain systems, and mechanical level indicators, firefighting equipment.

Product

Model No: 100

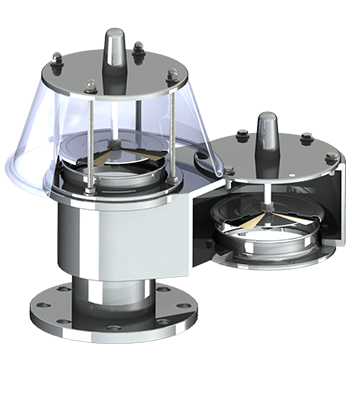

Pressure Vacuum Relief Valve

ERGIL Storagetech™’s Model 100 Pressure Vacuum Relief Valve provides protection to bulk storage tanks and vessels from over and under pressurisation. The valves are mounted on the tank roof flange or a vent pipe from the vapour space.

In the closed position the pressure relief pallet and diaphragm assembly is held tightly against a seal to prevent the loss of vapour to the atmosphere. As the internal pressure in the tank increases, due to product filling and vapour development, the pressure in tank increases and in the event that the set pressure of the unit is reached, the diaphragm will open and discharge the gas to the atmosphere. The opening set-point is selectable from a range +2.0 mbar and +60 mbar. (+0.8 inch W.C and +24 inch W.C), and the valve will reseal when the tank returns to a safe pressure.

Model No: 101

Pressure Vacuum Relief Valve

ERGIL Storagetech™’s Model 101 Pressure Vacuum Relief Valve provides protection to bulk storage tanks and vessels from over and under pressurisation. The valves are mounted on the tank roof flange or a vent pipe from the vapour space.

In the closed position the pressure relief pallet and diaphragm assembly is held tightly against a seal to prevent the loss of vapour to atmosphere. As the internal pressure in the tank increases, due to product filling and vapour development, the pressure in tank increases and in the event that the set pressure of the unit is reached, the diaphragm will open and discharge the gas to atmosphere. The opening set-point is selectable from a range between +61 mbar and +1000 mbar (+24 inch W.C. and 400 inch W.C.), and the valve will reseal when the tank returns to a safe pressure.

Model No: 300

Flame Arrestor

ERGIL Storagetech™ Model Number 300 Flame Arrester is a safety device that has a flame barrier with a large number of defined passage gaps, whose gap cross section is set withregard to the properties of the flowing gas, is cooled effectively and secured against a flame flashback in the case of continuous combustion. They are typically mounted to a flange or pipe. which connects the vapor space of a storagetank or a pipeline.

Standard sizes: 1” to 12” DN25 to DN300

Body / Flanges: 1) Carbon steel

2) Stainless steel AISI 316 –L or 304-L

3) Aluminium

4) Customer Specification

Flange drilling: API Class 150, PN16, and Special

Flame element: Stainless steel AISI 316 –L or 304-L

O-ring seal: Nitrile, Special

ATEX cert: Ex II 1/2 G IIB

Model No: 320

Flame Arrestor

ERGIL Storagetech™ Model 320 In-line Detonation Flame Arrester is designed for installation in gas pipelines. Detonation occurs when a flame travelling through the pipeline reaches supersonic velocities, usually as a result of thepipeline configuration or pipeline surface roughness. Changes in gas density and pressure causes the flame velocity to metamorphose from subsonic to supersonic.

Standard sizes: 1” to 12” DN25 to DN300

Body / Flanges: 1) Carbon steel

2) Stainless steel AISI 316 –L or 304-L

3) Aluminium

4) Customer Specification

Flange drilling: API Class 150, PN16, and Special

Flame element: Stainless steel AISI 316 –L or 304-L

O-ring seal: Nitrile, Special

ATEX cert: Ex II 1/2 G IIB

Model No: 301

Flame Arrestor

The flame quenching element is designed to be three or four times the area of the pipe in which it is installed, and is assembled between two flanged reducing spools. The element comprises a tightly rolled scroll or scrolls of crimped stainless steel ribbon to form passages through which the vapour passes. The area of each passage determines level of protection that the element provides. ERGIL Storagetech™’s Model 300 In-line Deflagration Flame Arrestor has a Maximum Experimental Safe Gap as per standard, and is suitable for gas groups IIB and IIA.

Standard sizes: 1” to 12” DN25 to DN300

Body / Flanges: 1-) Carbon steel

2-) Stainless steel AISI 316 –L or 304-L

3-) Aluminium

4-) Customer Specification

Flange drilling: API Class 150, PN16, and Special

Flame element: Stainless steel AISI 316 –L or 304-L

O-ring seal: Nitrile, Special

ATEX cert: Ex II 1/2 G IIB

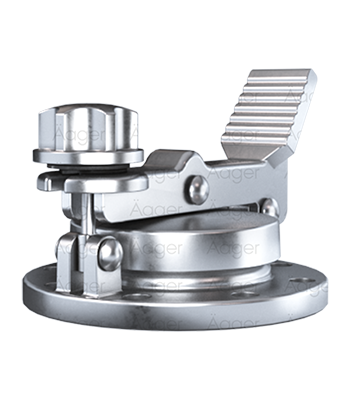

Model No: 210

Gauge Hatch (With lock)

ERGIL Storagetech™’s Model 210 Lockable Gauge Hatch has a locking-screw to prevent inadvertent or unauthorised opening. Operated by foot or knee, it leaves the operator hands-free to dip the tank’s contents for depth, take product samples, and obtain temperature measurements.

Setting Range

Pressure: Weight-loaded up to 15mbar

Ambient temp: -20°C to +60°C

Construction

Standard sizes: 2” to 8” 200mm

Flanges: API Class 150 RF, DIN raised-face

Body: Carbon steel, 316 stainless steel, cast aluminium, cast iron

Paint finish: 1) Powder Coating, Colour RAL 9006

2) Epoxy Paint, Colour RAL 9006

3) Customer Specification

ATEX cert: Ex II 1/2 G c IIB

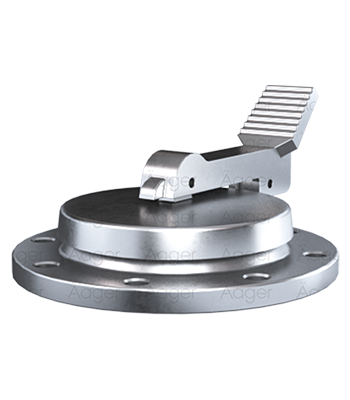

Model No: 200

Gauge Hatch

Storagetech™’s MODEL 200 Gauge Hatch offers a simple and easy access into the vapour space of bulk storage tanks. Opened by foot or knee, it leaves the operator hands-free to dip the tank’s contents for depth, take product samples, and obtain temperature measurements.

Setting Range

Pressure: Weight-loaded up to 15mbar

Ambient temp: -20°C to +60°C

Construction

Standard sizes: 2” to 8” 200mm

Flanges: API Class 150 RF, DIN PN16

Body: Carbon steel, 316 stainless steel, cast aluminium, cast iron

Paint finish: 1) Powder Coating, Colour RAL 9006

2) Epoxy Paint, Colour RAL 9006

3) Customer Specification

ATEX cert: Ex II 1/2 G c IIB

Model No: 400

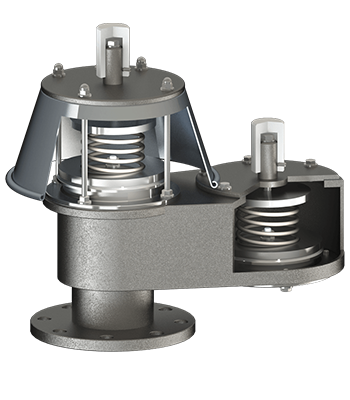

Emergency Pressure Relief Vent (Weight loaded)

The Model 400 Weight-loaded Emergency Relief Vent operates in the last resort when a vessel or storage tank is exposed to a large-scale fire, and the standard pressure relief valve has failed to open or cope with the extreme conditions.

Setting Range

Pressure: Weight-loaded +2.0 mbar and +60 mbar. (+0.8 inch W.C and +24 inch W.C)

Ambient temp: -20°C to +60°C

Construction

Standard sizes: 6” to 30” 150 to 750mm

Body / Flanges: Carbon steel, Stainless steel 316 or 304, Customer Specification

Flanges drilling: API Class 150, DIN PN 16, Special

Seals: Nitrile, Special

Paint finish: 1) Powder Coating, Colour RAL 9006

2) Epoxy Paint, Colour RAL 9006

3) Customer Specification

ATEX cert: Ex II 1/2 G c IIB