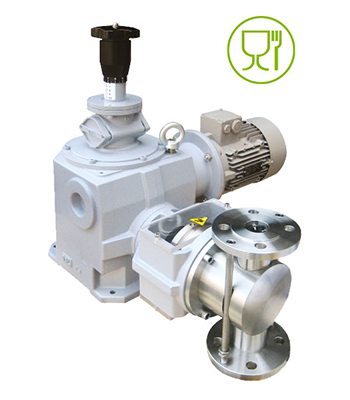

Metering Pump / Diaphragm Pump

OBL as a leading manufacturer of metering pumps and polymer make up systems. Over the decades innovative products have been developed to include solenoid , mechanical ,hydraulic and plunger diaphragm pumps and polymer make up units

Established in 1975 recently joined IDEX Corporation in 2010.

Manufacturing is 100% European (designed, assembled, tested in OBL)

Product

M Series

Mechanical DiaphragmRobust and reliable spring return mechanical diaphragm pump. The double-layer PTFE membrane grants a high chemical compatibility, the pump body is made of aluminum and coated through a cataphoresis process to increases resistance to chemical and atmospheric agents. These features, combined with a great dosing accuracy and very low maintenance, make this pump the ideal solution for applications in the water treatment industry, power generation, pulp and paper and many more.

R Series

PlungerR series plunger metering pumps are ideal for dosing chemicals at high pressure with unsurpassed precision. A specific design allows for dosing high-viscous chemicals at high temperatures while granting a steady accuracy and great reliability. Ideal for industrial applications that requires dosing of glue, emulsion, coating agents, oils and greases and many other chemicals.

XRN Series

Hydraulic DiaphragmThe first compact hydraulic diaphragm pump with integrated safety valve. This solution combines the simplicity and cost-effectiveness of the spring return with the advantages of the hydraulic diaphragm, using an innovative mechanically actuated oil replenishing system, representing the ideal solution also for process applications. The very small dimensions and the integration of a safety valve contribute to reducing the costs of construction and operation of the installation and to increase its intrinsic safety.

L Series

PlungerCapable of handling pressures up to 500 barg (7.252 psi) and flowrates up to 5.500 lt (1.210 gph) in single-head configuration, the plunger L series pump is ideal demanding industrial applications such as high-pressure boiler feed, catalysts dosing, scale and corrosion inhibitors dosing. Designed to meet the highest standards in metering industry, this positive return plunger pump has a modular design that can house multiple heads to perfectly match your dosing needs. Separate oil reservoirs reduce the risk of oil contamination of process liquid and ensures steady and accurate output.

XL Series

Hydraulic DiaphragmThe XL’s are rugged and very accurate single-block positive return hydraulic diaphragm pumps suitable for high demanding 24/7 industrial applications. Built in full compliance with API675 and ATEX 2014/34/UE standards, these pumps house a relief valve, an air purge valve, and a mechanically actuated self-replenishing hydraulic system. These features combined protect the pump and the whole dosing system from damages due to overpressures, while granting a proper chemical dosing under any circumstances.

LX9 Series

Hydraulic DiaphragmThe combination of unmatched metering accuracy, robustness and reduced footprint make the L X9 hydraulic double-diaphragm pump the ideal solution for a wide spectrum of industrial dosing processes. The positive return mechanism (lost motion) grants a high reliability and durability, while the built-in safety and purge valve allow for a constant suction lift and chemical dosing under any working condition. Allowing for a multi-head configuration to match any dosing need, the L X9 pumps include a diaphragm rupture detection system, and comply in full with API675 and ATEX 2014/34/UE standards.