Heat Exchanger Tube Plugs and Pressure Testing Equipment

Made in USA

PRODUCT

POP-A-PLUG® CPI/PERMA

Heat Exchanger Tube Plugs

Pop-A-Plug Tube Plugs install hydraulically in minutes with an engineered breakaway while offering a controlled installation force to limit operator fatigue and prevent damage to tubes, tubesheets, and surrounding tubes.

Pressure Rating: Up to 1,000 PsiG (68.9 BarG)

Size Range: 0.472” to 2.067” (11.99mm to 52.5mm) Tube I.D.

Standard Materials: Brass 360/464, Carbon Steel (1018 & 1045), 304/304L Stainless Steel, Copper Nickel 70/30, 316/316L Stainless Steel, Titanium

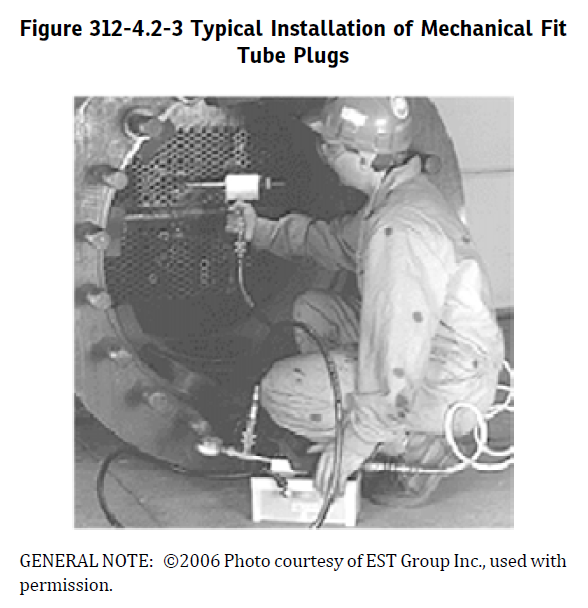

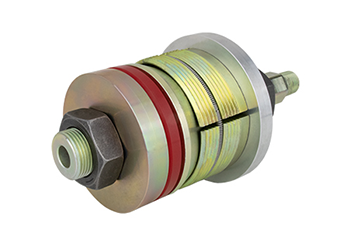

POP-A-PLUG® P2

High Pressure Tube Plugs

Pop-A-Plug P2 High Pressure Tube Plugs provide a permanent mechanical tube plugging solution for leaking heat exchanger tubes without welding, eliminating potential circumferential cracking and other heat related issues associated with welding.

Pressure Rating: Up to 7,000 PsiG (483 BarG)

Size Range: 0.400” to 1.460” (10.16mm to 37.08mm) Tube I.D.

Standard Materials: Brass 360/464, Carbon Steel (1018 & 1045), 304/304L Stainless Steel, Copper Nickel 70/30, 316/316L Stainless Steel, Titanium

POP-A-PLUG® Removal Tool

For Fast, Reliable Removals - No Air or Electricity Needed

• Removes Installed Plugs Quickly and Easily

• Works on All Styles of Pop-A-Plugs®

EST's Pop-A-Plug® Removal Tool (PRT) is the ideal companion to our Pop-A-Plug Installation Tools - perfect for removing installed Pop-A-Plugs when it comes time to retube, sleeve or retire the bundle.

G-160 TUBE TESTING TOOL

Heat Exchanger Maintenance Starts With a Tube Leak Testing Tool You Can Rely OnEarly detection of leaking tubes in heat exchangers, boilers and condensers is essential to avoiding costly downtime. G-160 Tube Testing Tools from EST Group rapidly detect leaks while providing a safer environment for plant personnel. Innovative patented gripper design provides increased operator safety. Operates with compressed air.

GRIPTIGHT® Test Plug

Pressure Test Open-end Pipe & Tubing

GripTight Test Plugs provide a fast, safe and reliable solution for testing open ended pipe. Capable of achieving test pressures up to 14000 PsiG (960 BarG), GripTight Test Plugs eliminate the need for welding on and cutting off end caps, saving time and money on every test

• I.D. Sealing Version

• Pressures to 14,000 psi (960 Bar)

• Sizes from .93" to 8.53" (23.6mm - 216.7mm) In Stock

• Larger Sizes through 42" (1066.8 mm) Available

GRIPTIGHT® Elbow Test Plug

Hydrostatic Pressure Testing Solution for Long Radius Elbows

GripTight Elbow Test Plugs reduce testing time by up to 90% over conventional methods by eliminating the need to weld on and cut off end caps to perform hydrostatic pressure tests. A time consuming process that can be both expensive and labor intensive.

Test Pressure: 3,350 PsiG (231 BarG)

Size Range: 2” to 24” (DN50 to DN600)

Standard Seal Materials: Urethane